Understanding SMED...

SMED

stands for Single Minute Exchange of Die.

Developed by Dr. Shigeo Shingo to help Toyota lower the cost of line

set-up to change models SMED is a part of Lean programs worldwide.

SMED is a tool, a lean production method, a theory, and techniques

for performing set-up, cleaning, or PM in less than ten (10)

minutes.

-

SMED covers all types of scheduled downtime events to a line or operation.

-

SMED becomes more important to lower the cost of change-over in high mix operations.

-

SMED teams analyze their work and tools to streamline the change-over/set-up times.

-

SMED is very important because some companies find that the set-up time is both large and variable.

-

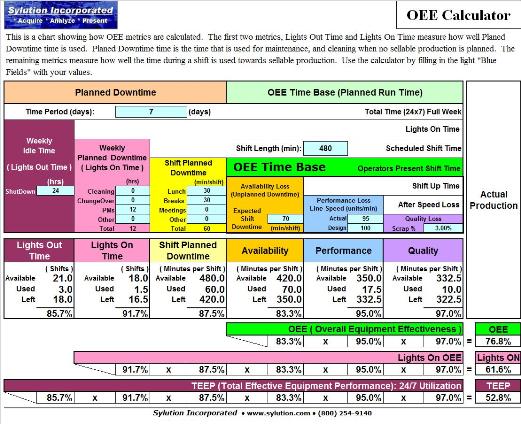

SMED is important because the set-up time affects OEE, TEEP and many other performance metrics.

Set-up and PM functions can cause unscheduled downtime if performed poorly. Sloppy set-up of line may result in increased performance loss and higher quality losses. Some have found that it is important to measure not just the SMED event time but the line performance after the SMED event.

Real-time Performance Management Systems

We all know that some of the teams that are working hard on SMED are still using the same tools as Dr. Shingo likely used in the 1950s - a stop watch, clip board, and good pair of shoes to stand on concrete floors all day.

Today, a manufacturing intelligence dashboard can bring together historical SMED Event times in a graph, journal entry of change to SMED team or procedures, and the exact performance downtime and quality data from the controllers during startup after the SMED event. Together, these pieces of intelligence become a powerful tool.

The picture below shows a manufacturing performance chart by Sylution Incorporated. The downloadable Excel version allows you to play around with the numbers to see how improvements to net operating time and performance increase the metrics and good units out the door.

Complete the download request below to receive an Excel copy of the Sylution OEE Calculator.

Click Here to download the Sylution OEE Calculator