Understanding OEE...

OEE stands for Overall Equipment Effectiveness. OEE is a performance metric based on three other metrics:

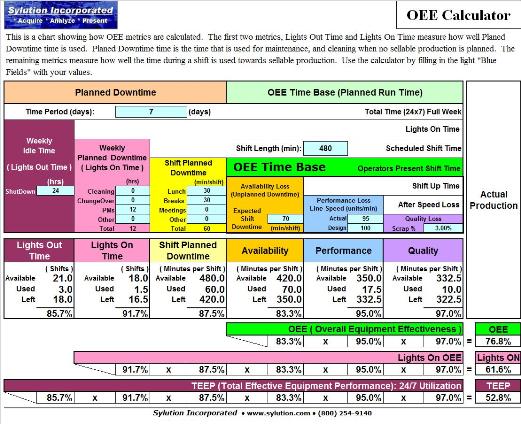

OEE = Availability X Performance X Quality

OEE is a valuable metric to understand performance but it is even more valuable when you look at the other three metrics that make up OEE.

Availability:

Availability accounts for downtime losses as a function of the total planned operating time.

Availability = Operating Time / Planned Operating Time (Operators Present)

Performance:

Performance captures speed and micro-stop losses.

Performance = Actual Rate / Theoretical or Ideal Rate

Quality:

Quality quantifies the losses from quality rejects.

Quality = Good Product / Total Product

Other Performance Metrics:

A good Real-Time Performance Management Solution will provide a user with more that just OEE, Availability, Performance and Quality reporting and dashboards.

Also look at these handy manufacturing metrics:

-

Adjusted OEE

-

TEEP

-

Cycle-time

-

Rate

-

Actual time for Planned downtime events like cleaning, Changeover, PMs, etc.

The picture below shows a manufacturing performance chart by Sylution Incorporated. The downloadable Excel version allows you to play around with the numbers to see how improvements to net operating time and performance increase the metrics and good units out the door.

The OEE Calculator below is free.

|

|

Cost: $ 0.00 |

| Order to download the OEE Calculator for free. |